Paper is produced worldwide and in turn, waste is produced in large amounts. With tons of this usable pulp being produced, you would think that there would be more options for how paper mills could recycle it. Our class was asked how we might approach this problem with our knowledge of chemistry, finding a way to recycle the pulp byproduct.

Aerogel's super-insulation properties.

Bio-foam insulation being sprayed.

Paper mill waste in it's raw form.

Background:

A graduate student in agriculture at the Hebrew University of Jerusalem has developed a cost-efficient way of creating aerogels or foam from the waste of paper mills, radically reducing waste from paper production and creating two products that are highly valuable and in demand. I looked for chemical properties as well as physical properties that would allow for me to turn the pulp into foam which could be used in packaging, insulation, shoes, and other uses throughout the world. Aerogel can be used as a super-insulator in space suits (a huge new frontier in the financial world).

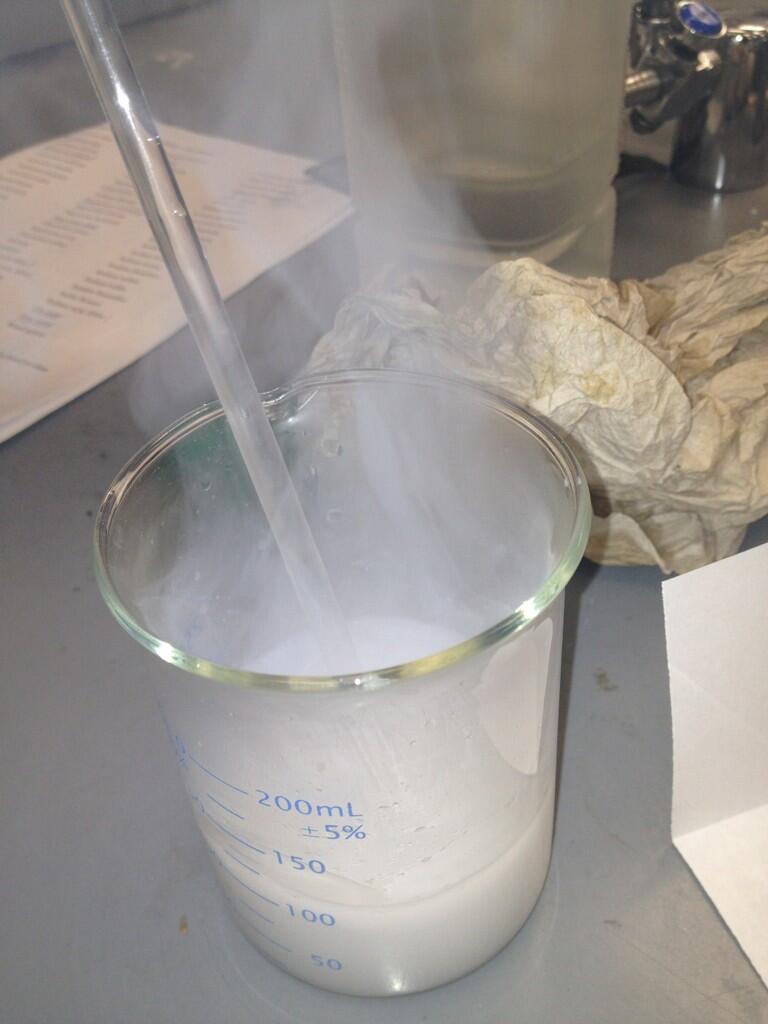

To produce aerogel foam from cellulose, the larger glucose must be broken down. Acid hydrolysis can be used to obtain the smaller fibers as pictured below:

(C6H12O6)n + HCl = HO + Cl + C6H11O5

These smaller fibers are a perfect feed-stock for nano-crystalline cellulose (NCC). This can be formed using relatively low energy and chemical input compared to paper-making itself. Furthermore, they developed a technique to process the NCC into composite foams. Although I was unable to access any of this information (or much of the equipment required for the processes), I believe that this would be very useful in the very industrialized world we live in.

Data/Analysis:

30ml Hcl + waste pulp

In this reaction, I added the pulp into the HCl until no reaction occurred. I then filtered the product (water and finer pulp). The finer fibers of the pulp were able to pass through the fine plastic mesh filter. These finer fibers are what allow for NCC to be produced. The other product could be used as a building material or something else. The NCC could then be used to produce aerogels and foams.

Conclusion:

I should have pulled some of the other materials and elements from the waste like the aluminum, calcium carbonate, and other miscellaneous things. This would have made a finer product for NCC production and in the end, a finer foam. I would like to research the process more and find how it may be applied to produce a non-composite foam. One of my biggest flaws in my experiment was being unable to fully produce foam or aerogel.

Citations:

Bio-foam insulation being sprayed.

Paper mill waste in it's raw form.

Background:

A graduate student in agriculture at the Hebrew University of Jerusalem has developed a cost-efficient way of creating aerogels or foam from the waste of paper mills, radically reducing waste from paper production and creating two products that are highly valuable and in demand. I looked for chemical properties as well as physical properties that would allow for me to turn the pulp into foam which could be used in packaging, insulation, shoes, and other uses throughout the world. Aerogel can be used as a super-insulator in space suits (a huge new frontier in the financial world).

To produce aerogel foam from cellulose, the larger glucose must be broken down. Acid hydrolysis can be used to obtain the smaller fibers as pictured below:

(C6H12O6)n + HCl = HO + Cl + C6H11O5

These smaller fibers are a perfect feed-stock for nano-crystalline cellulose (NCC). This can be formed using relatively low energy and chemical input compared to paper-making itself. Furthermore, they developed a technique to process the NCC into composite foams. Although I was unable to access any of this information (or much of the equipment required for the processes), I believe that this would be very useful in the very industrialized world we live in.

Data/Analysis:

30ml Hcl + waste pulp

In this reaction, I added the pulp into the HCl until no reaction occurred. I then filtered the product (water and finer pulp). The finer fibers of the pulp were able to pass through the fine plastic mesh filter. These finer fibers are what allow for NCC to be produced. The other product could be used as a building material or something else. The NCC could then be used to produce aerogels and foams.

Conclusion:

I should have pulled some of the other materials and elements from the waste like the aluminum, calcium carbonate, and other miscellaneous things. This would have made a finer product for NCC production and in the end, a finer foam. I would like to research the process more and find how it may be applied to produce a non-composite foam. One of my biggest flaws in my experiment was being unable to fully produce foam or aerogel.

http://en.wikipedia.org/wiki/Nanocrystalline_cellulose